Uporaba tehnologije večplastnega so-ekstrudiranja v proizvodni liniji cevi iz HDPE

2025

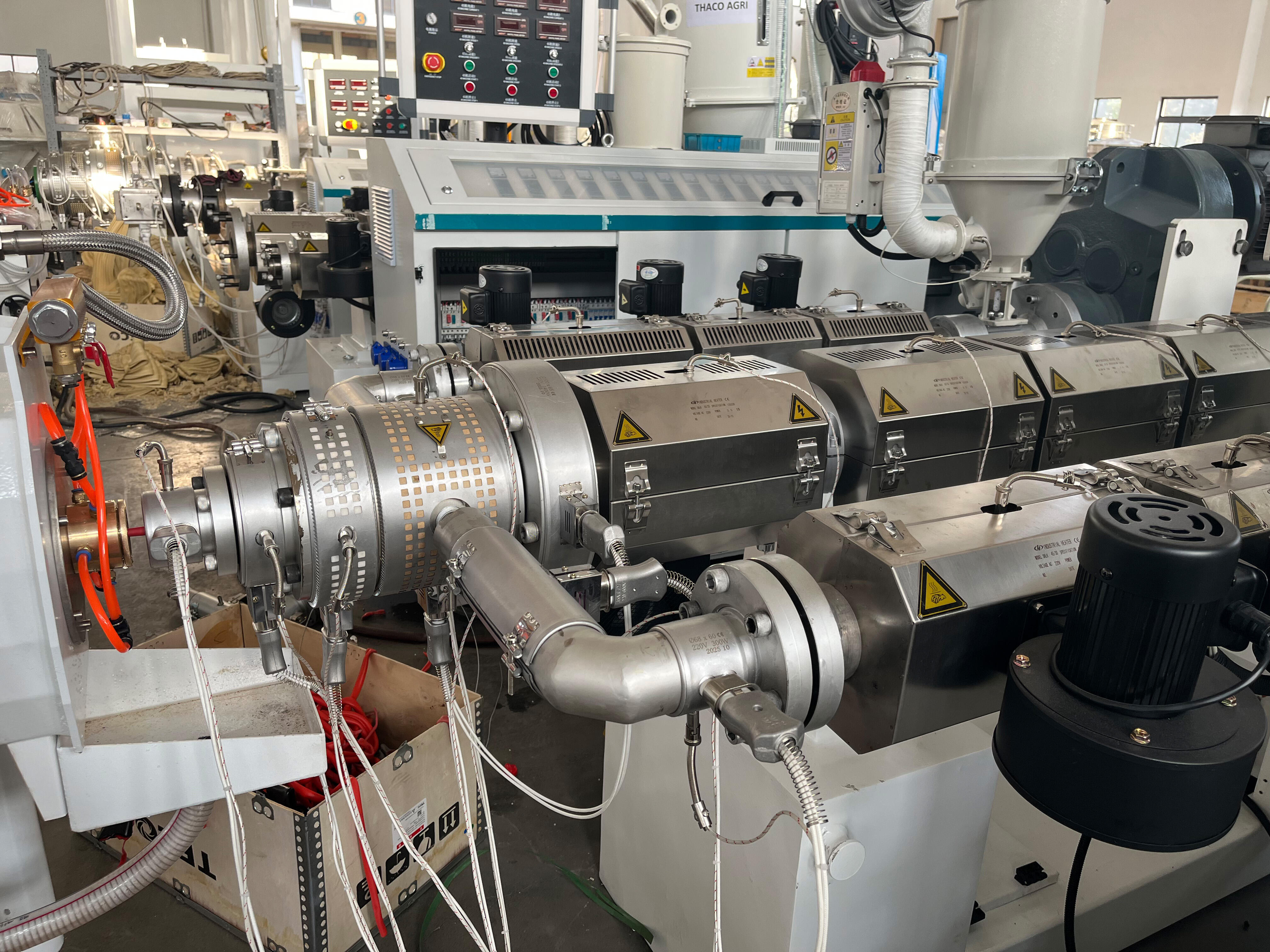

Raziskave uporabe tehnologije triplastne koekstrudiranja v proizvodnih linijah za cevi iz HDPE se predvsem osredotočajo na izboljšanje funkcionalnosti, trdnosti in učinkovitosti proizvodnje cevi s pomočjo kompozitnih materialov in konstrukcijskega dizajna. Spodaj so navedene konkretne aplikacije in prednosti te tehnologije pri različnih vrstah cevi HDPE:

I. Tehnična izvedba in ključne prednosti

1. Oblikovanje večplastne kompozitne strukture

Tehnologija triplastne koekstrudiranje omogoča brezševno zlepek polietilena (PE), EVOH in lepil s pomočjo neodvisnih ekstruderskih sistemov in natančnih kalupov, pri čemer nastane materialni sistem, ki združuje togost in fleksibilnost. Na primer, HDPE triplastna kompozitna tiha odtočna cev podjetja Jiangsu Xinhe uporablja srednji penasti sloj + gladke notranje in zunanje strukture, kar znatno izboljša zmanjšanje hrupa in odpornost proti tlaku.

2. Izboljšanje zmogljivosti

Zmanjšanje hrupa: Vijačna struktura na notranji steni zmanjšuje hrup s turbulentnim tokom, kar zmanjša raven hrupa pod 45 decibelov, zaradi česar je primerna za bolnišnice, šole in druge objekte z visokimi zahtevami glede hrupa.

Upornost pred temperaturo in korozijo

Cev lahko dolgoročno prenese delovne temperature do 70 °C, ohranja udarnost pri -20 °C ter kaže dobro odpornost proti neoksidativnim kislinam (kot sta hlorovodikova kislina in razpršena žveplova kislina).

II. Optimizacija proizvodnje in inovacije v procesih

Razporeditev opreme in nadzor cikla: Proizvodna linija uporablja U-obliko ali ravno postavitev za optimizacijo toka materiala ter zmanjšuje nakopičevanje in čas čakanja tako, da zagotavlja enakomeren ciklusni čas opreme, s čimer izboljšuje proizvodno učinkovitost.

Zagotovilo natančnega procesa: Podjetja, kot je Jiangsu Xinhe, uporabljajo večkratne inspekcije natančnih procesov, da zagotovijo tesnenje izdelkov in zmanjšanje hrupa. Uporabljajo tudi sistem razvrščanja z umetno inteligenco za izboljšanje stopnje prepoznavanja nečistoč na 99,8 %.

III. Raziširitev scenarijev uporabe: Tehnologija tristranskega koekstrudiranja se uporablja ne le za tihe odtočne cevi, temveč tudi v komunalnem inženirstvu (npr. integrirani koridorji za cevi) in industrijskih panogah (npr. odvajanje kemičnih odpadnih voda). Njena visoka obročna togost in tlakna trdnost omogočata nadomeščanje tradicionalnih kovinskih cevi.

Povzetek: Z inovacijo sestave materialov in procesa tehnologija trojne koekstrudiranje znatno izboljša zmogljivost cevi iz HDPE v scenarijih, kjer je potrebna tiha obratovanja, odpornost proti tlaku in koroziji, hkrati pa upošteva zahteve po učinkovitosti proizvodnje in varstvu okolja.

EN

EN

AR

AR

BG

BG

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MK

MK

HY

HY

AZ

AZ

UR

UR

BN

BN

LA

LA

NE

NE

MY

MY

KK

KK

UZ

UZ